Search Filter

Premium Monoblock Wheels — Built to Order

Tailored fitments, motorsport-grade integrity, and finishes that elevate every detail. Engineered in the USA. Made to fit your vehicle—perfectly.

Lead time: 8–12 weeks |

Hub-centric | TPMS compatible |

JWL/VIA compliant

Standard Finishes

Popular options shown below.

Gloss|Satin Black

Gloss|Satin Bronze

Signature Finishes

Custom colors on request.

Brushed Titanium

Polished

Engineered To Last

Flow‑Optimized

Finite‑element designed for strength‑to‑weight.

Made‑to‑Fit

Offsets, bolt patterns & centerbores dialed to your exact chassis.

Finish Lab

Brushed, tinted clears, satin blacks, gloss silvers & more.

What you can expect

1:1 fitment consultation

CAD confirmation for brake clearance.

Trusted engineering

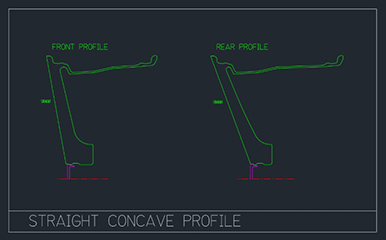

Perfect fitment with maximum concave.

Monoblock precision, without compromise

Each Element Forged wheel begins as a forged blank and is CNC machined to your vehicle. We validate big brake profiles (BBK), clearances, and load ratings to OEM or better. The result: sharper turn‑in, reduced un-sprung mass, and a fit that looks factory‑perfect—only better.

ISO‑9001 Facility | T6 Heat Treat 6061‑T6 Forged | CNC 5‑Axis

Popular Fitments

These are example baselines; we custom‑machine to your exact brake and suspension setup.

| Make/Model | Size (F/R) | Profile | Notes |

|---|---|---|---|

| Audi RS6 Avant (C8) | 22×10.5 | Straight Concave | BBK clear; flush stance |

| Mercedes S580 (W223) | 21×9.5 / 21×10.5 | Radius Concave | OEM TPMS & hub |

| Ford Mustang GT (S550) | 20×10 / 20×11 | Compound Concave | PP1 & Brembo compatible |

| Ram 1500 (DT) | 22×10 | Multi Facet Concave | No rub at stock height |

The Process

Spec & Approve

We start by gathering the exact specifications of your vehicle — including brake clearances, suspension setup, and stance preferences. From there, our engineering team creates precise CAD renderings of your wheels. Upon request you’ll have the chance to review and approve the design before production begins, ensuring everything matches your vision.

Forge & Machine

Each wheel begins with aerospace-grade 6061-T6 forged aluminum blanks, chosen for their superior strength-to-weight ratio. Using advanced CNC machining, the blanks are cut to exact tolerances, achieving both structural integrity and a flawless design profile.

Finish & Ship

Every wheel undergoes a final quality control inspection before finishing. We apply your chosen surface treatment, whether that’s brushed, polished, powder-coated, or custom-colored. Once complete, your wheels are carefully packaged and shipped, arriving ready to mount on your vehicle.

Customer Builds

Tesla Model S on Element Forged ME-2

Frequently Asked Questions

- How long is the build time?

- Typical monoblock lead time is 8-12 weeks depending on finish and current queue.

- Do you guarantee brake clearance?

- Yes—We’ll verify in CAD with our extensive BBK in-house catalog.

- Can you match OEM TPMS?

- Yes. Our wheels are TPMS compatible and hub‑centric to your vehicle.

- What finishes can I choose?

- Brushed clears, gloss/satin blacks, tinted clears, satin silvers, and custom colors on request.

- Can my factory center caps fit?

- Yes-We can machine to accept OE caps on request. Your Order will ship with no caps included.

Ready to spec your set?

Our specialists will dial in your fitment and finish. No pressure—just precision.

Still have a few questions?

Why enthusiasts choose Element

- Arizona‑based team with 20+ years of fitment experience

- Strict SKU and fitment validation across platforms

- Fast & FREE shipping

- Responsive support by phone, chat, or email

Recent Ratings

Verified reviews across Google & Yelp.

Service

★★★★★

Fitment Accuracy

★★★★★

Packaging

★★★★★

“Perfect fitment on my RS6. Communication and lead time were exactly as promised.”

— Bradley R.